The difference between using biodegradable film and traditional non degradable plastic film, as well as their impact on soil, is mainly reflected in the following aspects:

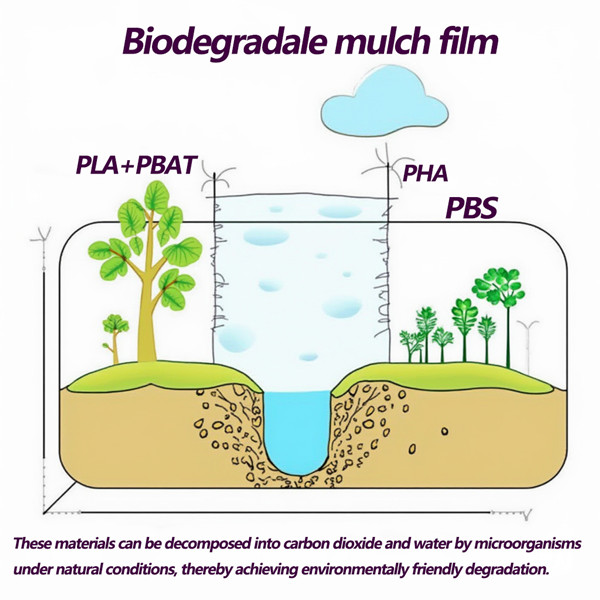

Biodegradable mulch film: Natural polymer materials (such as corn starch, calcium carbonate,cellulose), polylactic acid (PLA),Poly butyleneadipate-co-terephthalate (PBAT) polyhydroxyalkanoates (PHA) and other biobased materials are usually used, or polyethylene treated by modification technology (such as adding biodegradable agents) is used. These materials can decompose into water, carbon dioxide, and biomass under specific environmental conditions (temperature, humidity, microbial activity) under the action of microorganisms such as fungi and bacteria, with a degradation cycle generally ranging from several months to two years.

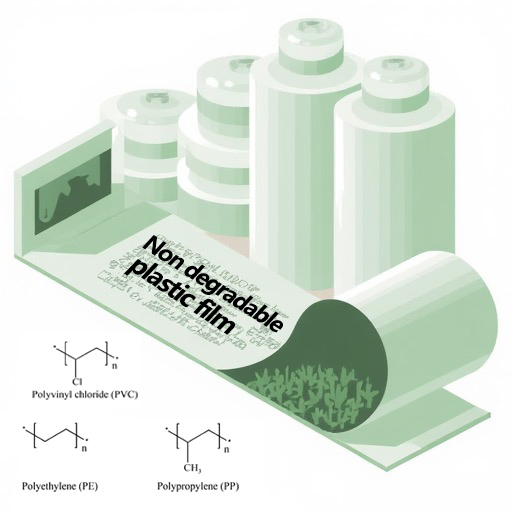

Traditional non degradable plastic film: mainly made of petrochemical based materials such as polyethylene (PE) and polyvinyl chloride (PVC), with a natural degradation cycle of several decades or even hundreds of years, which can easily form soil residues.

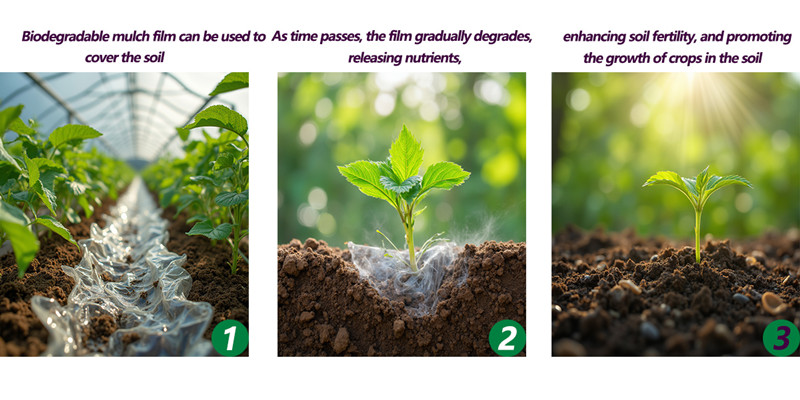

Biodegradable mulch film:

Soil structure: Degradation products (such as humus) can improve soil porosity, promote the formation of aggregate structure, and enhance soil water and fertilizer retention capacity.

Microbial activity: The degradation process provides a carbon source for soil microorganisms, enhances microbial community diversity, and promotes nutrient cycling (such as nitrogen fixation and phosphorus activation).

Residual risk: Thoroughly degrade and reduce the long-term interference of plastic particles on soil ecosystems.

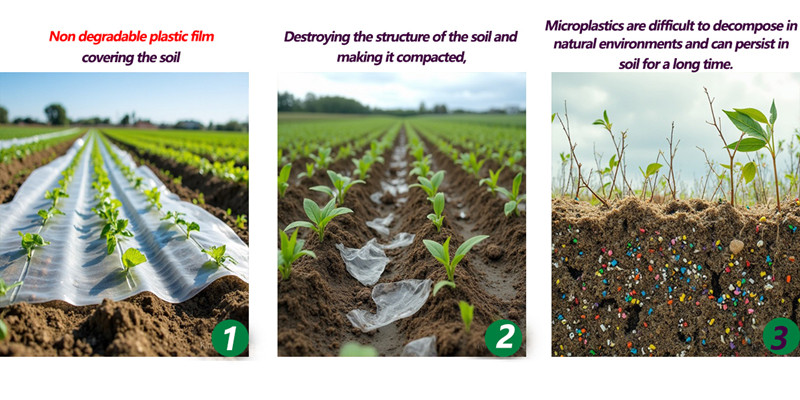

Non degradable plastic film:

Soil structure: Residual film blocks the vertical movement of soil moisture, leading to surface compaction and hindered root penetration, which may accumulate over time and form a "plastic isolation layer".

Microbial inhibition: Polyethylene film hinders soil gas exchange, reduces aerobic microbial activity, and affects the efficiency of organic matter decomposition.

Residual hazards: Microplastic particles may be absorbed by crop roots, transmitted through the food chain, or enter groundwater systems with irrigation.

Biodegradable mulch film:

Management cost: No need for manual recycling, saving labor costs, but the initial material cost may be higher than traditional plastic film.

Applicable crops: Suitable for annual planting or crops with short rotation cycles (such as vegetables and flowers), to avoid residual effects on the next crop.

Non degradable plastic film:

Management cost: Regular mechanical or manual cleaning is required, resulting in low residual film recovery rate (about 30% -50%) and high residual rate, which makes subsequent cultivation difficult.

Long term risk: Accumulated residues reduce soil productivity, which may lead to environmental regulatory penalties related to "white pollution".

Biodegradable mulch film: conforms to the concept of circular agriculture, reduces dependence on petrochemical resources, and lowers greenhouse gas emissions (compared to traditional PE film production, PLA life cycle carbon emissions can be reduced by 30% -50%).

Non degradable plastic film: exacerbates the problem of plastic waste, soil residue affects sustainable farming, and conflicts with agricultural "plastic ban" policies in regions such as the European Union and China.

matters needing attention:

The effectiveness of biodegradable mulch film is limited by environmental conditions (such as slow degradation rate in low-temperature areas), and products that are suitable for the regional climate need to be selected.

Some "pseudo degradation" products (such as PE films with only a small amount of degradation agent added) have limited actual degradation effects and require verification of third-party certification (such as ASTM D6400, EN 13432 standards).

In summary, biodegradable mulch films provide a more sustainable solution for agricultural ecosystems through environmentally friendly degradation mechanisms, while reducing soil pollution risks.