On April 22, 2024, the official WeChat account of the United Nations announced on International Mother Earth Day that plastic pollution has become one of the most severe challenges for the Earth and humanity. The global demand for biodegradable plastics is expected to exceed 20 million tons by 2025. According to Ji Junhui, director of the National Engineering Research Center for Engineering Materials, Institute of Physics, Chinese Academy of Sciences, the replacement of degradable plastics is an important way to reduce the source of plastic pollution. By the end of 2025, the global demand for biodegradable plastics will reach more than 20 million tons.

The United Nations plans to reach a legally binding intergovernmental agreement on global governance of plastic pollution by the end of 2024. However, there is currently no consensus among countries on how to address plastic pollution. Developed countries in Europe and America began commercial production of biodegradable plastics in the 1990s, which were once seen as a solution to plastic pollution.

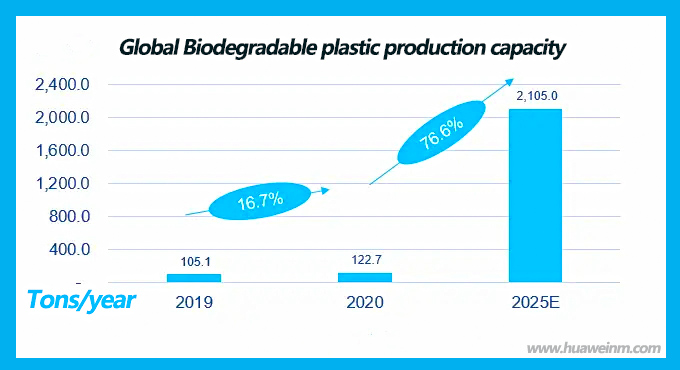

In the Chinese market, it is expected that by 2025, the demand for biodegradable plastics will reach 2.6 million to 4.413 million tons, and the market size is expected to exceed 50 billion to 90 billion yuan. In addition, China has become the world's largest producer of biodegradable plastics, with a total domestic production capacity of approximately 1.28 million tons of biodegradable plastics in 2023, accounting for 75% of the global production capacity. In 2020, globally biodegradable plastics were mainly used in the fields of packaging materials, agricultural films, and textiles, with packaging (including soft and hard packaging) being its most important application area. Among them, PLA and PBAT have great market development potential. Nature Works in the United States is a leading global PLA enterprise, and BASF in Germany is the most influential enterprise in the PBAT market. The increase in global biodegradable plastic production capacity from 2021 to 2025 will mainly be contributed by China. From a global perspective, if all newly disclosed production capacity is put into operation, it is expected that the global biodegradable plastic production capacity will reach 21.05 million tons per year by 2025.

Degradable materials:

1. Natural materials (cellulose, lignin, starch, chitosan);

2. Synthesize fully biodegradable polymer materials (fatty polyesters such as PLA, PBAT, PBS, PBST, PBSA, PPC, PGA, PCL, PPDO, and fatty aromatic copolyesters);

3. Multi component system: ① A multi-component system prepared between the above materials to regulate performance and function, such as PBAT/PLA/starch PBAT/PLA/PCL、PBAT/PGA;② The composite system composed of the above materials and natural mineral materials, such as PBAT/PLA/CaCO3, PBAT/PLA/Talc;③ The system composed of the above materials and environmentally friendly plasticizers, such as starch/glycerol, etc.

Non degradable materials:

Non biodegradable materials refer to non biodegradable polymer materials such as polyethylene, polypropylene, polystyrene, polyvinyl chloride, ethylene vinyl acetate, and polyethylene terephthalate.

Biodegradable plastic products represented by PLA, PBAT, etc. are rapidly degraded by microorganisms in the natural environment. This type of plastic is called fully biodegradable plastic, and disposing of it in the environment will not cause any environmental burden.

Light and oxygen degradable plastics have been recognized as "pseudo degradable" materials in many countries, but there is much controversy over the degradation time and degree of fully biodegradable plastics.

The essence of fully biodegradable plastics is to promote degradation by microorganisms. Currently, there are over 20 related products on the market, among which three types of products are relatively large in scale: first, starch based plastics mainly made from plant starch; The second is to use renewable plant resources (mainly corn) to extract and produce polylactic acid (PLA) polymers; The third type is the dicarboxylic acid diol copolyester (PBS, PBSA, PBAT, also known as PBS plastic) produced from petroleum by-products as raw materials.

The current clear degradation pathway for biodegradable plastics is composting degradation, including industrial composting and Home composting.

The scale, controllability of conditions, and temperature of the two are different, and the degradable products are also different. The temperature requirement for industrial composting is to maintain between 50 degrees Celsius and 65 degrees Celsius, while the temperature for household composting is generally below 45 degrees Celsius.

The household composting model is widely distributed globally, while industrial composting and its upstream and downstream industrial chains are only relatively complete in a few countries. For example, Italy's industrial composting facilities can basically cover the organic waste generated throughout the country, and the compost produced also has a backend market for sale; In countries such as the United States and Spain, industrial composting facilities exist in a few areas and do not cover the entire country.

Degradable plastics are one of the options for replacing plastic products in global policies to address plastic pollution, but they are not considered the primary alternative. The basic principle of the "upgraded version of the plastic restriction order" is to develop and promote plastic products and alternative products that meet performance standards, are green and environmentally friendly, and economically applicable, guided by the principles of recyclability, ease of recycling, and degradability. It aims to cultivate new formats and models that are conducive to regulating recycling and reuse, and reducing plastic pollution.

The upgraded version of the plastic restriction order proposes to prohibit the use of non degradable plastic bags in some areas and promote the use of environmentally friendly non plastic products such as cloth bags and paper bags, as well as degradable bags.