The process of degrading biodegradable bags through composting is as follows:

1. Material selection

Degradable bags are usually made of PLA (polylactic acid), PBAT (poly (adipic acid/butylene terephthalate) or starch based materials, Calcium carbonate modified material which can be decomposed by microorganisms under specific conditions.

2. Composting conditions

Composting degradation requires the following conditions:

-Temperature: 50-60 ° C, accelerates microbial activity.

-Humidity: 50-60%, maintain microbial activity.

-Oxygen: requires an aerobic environment to promote aerobic microbial decomposition.

-Microorganisms: An appropriate microbial community is required.

3. Degradation process

-Initial stage: The bag begins to physically decompose in a high temperature and high humidity environment.

-Microbial action: Microorganisms secrete enzymes to break down polymer materials into small molecules.

-Complete degradation: ultimately decomposed into carbon dioxide, water, and biomass, with no harmful residues.

4. Time

Under industrial composting conditions, degradation usually takes several weeks to several months, depending on the material, thickness, and composting conditions.

5. Home composting

Partially biodegradable bags can also be degraded in household composting, but for a longer period of time and under suitable composting conditions.

6. Precautions

-Distinguish types: Ensure that the bag is compostable and biodegradable, rather than ordinary plastic.

-Composting facilities: Industrial composting requires professional facilities, while household composting requires suitable conditions.

Through these steps, biodegradable bags can effectively degrade in composting environments, reducing environmental impact.

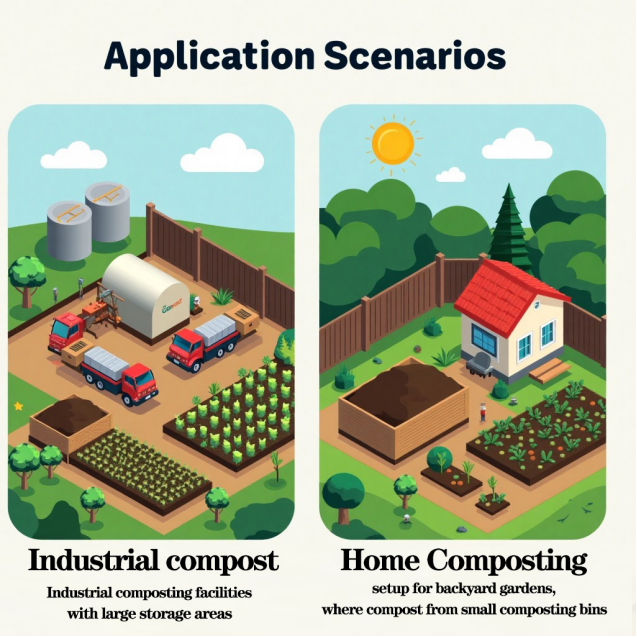

The biggest difference between home composting and industrial composting is mainly reflected in the following aspects:

• Home composting: Small scale, usually carried out in family courtyards, balconies, or indoors, dispersed in various households. The equipment is simple, and common ones include small manual or electric composting mixers, which are used to occasionally flip compost; Some families use simple composting bins to maintain the ventilation of the compost pile through natural ventilation. The composting process mainly relies on the action of natural microorganisms, and the technical content is relatively low.

Industrial composting: Large scale, centralized processing of large amounts of organic waste, usually requiring specialized facilities and sites. Adopting advanced mechanical equipment and technology, such as large flipping machines used to periodically flip the stack to ensure the ventilation of materials; There is a ventilation system and temperature control equipment to regulate the temperature and oxygen supply of the stack; We will also use microbial agents to accelerate the composting process and improve the quality of compost.

Home composting: Due to natural conditions, the composting process is slow and usually takes several months or even a year to fully decompose. Due to environmental conditions, operational methods, and other factors, the composting cycle is relatively long, usually taking several months to reach maturity.

Industrial composting: By strictly controlling temperature, humidity, ventilation, and other conditions, the composting speed is faster and can generally be completed within 180 days. Due to advanced equipment and technology, composting conditions can be better controlled. Generally speaking, the composting cycle is relatively short, usually ranging from a few weeks to about a month, and mature composting products can be obtained.

Home composting: mainly deals with plant-based waste generated by households, such as vegetable peels, coffee grounds, horticultural waste, etc. Due to temperature and condition limitations, it is not suitable for handling complex organic matter such as animal feces.

Industrial composting: can process a wider range of materials, including animal manure, food processing waste, etc., and can also process some organic matter that requires high-temperature sterilization.

Home composting: The conditions are relatively natural and greatly affected by the environment, making it difficult to accurately control temperature, humidity, and ventilation.

Industrial composting: Through professional equipment and technical means, the temperature, humidity, ventilation and other conditions during the composting process can be precisely controlled to ensure efficient decomposition.

Home composting: There are relatively few certification standards, and common ones include T Ü V AUSTRIA OK compost HOME from Europe and DIN CERTCO DIN Tested Garden Compostable.

Industrial composting: Certification standards are more stringent and extensive, such as DIN EN 13432 standard, and certified products can ensure complete degradation in industrial composting facilities.

Home compost: mainly used for home gardens or small gardening projects, reducing garbage emissions while providing fertilizer for household plants.

Industrial composting: mainly used for centralized treatment of urban organic waste, producing high-quality compost products for use in agriculture, horticulture and other fields.

Industrial compost: The product undergoes strict quality testing and has relatively stable and high quality. It can be sold as a commercial fertilizer in the market and used in agricultural production, landscaping, and other fields. It can provide rich organic matter and nutrients to the soil and improve soil structure.

Home compost: The product quality is affected by various factors and may not be stable enough, but it can meet the needs of home gardening. It is used to improve the soil of home gardens, balcony flower pots, etc., provide nutrients for plants, and promote plant growth.

In summary, household composting is more suitable for small-scale, natural environment organic waste treatment, while industrial composting is more suitable for large-scale, centralized treatment and can more efficiently convert organic waste into high-quality fertilizers.