Bio starch-based resin is often derived from various biomass sources, the most widely utilized being starch, which is a natural polymer that can be incorporated into different materials. Starch-based plastics can be used in a variety of applications since they can be incorporated with different petroleum-based polymers or biopolymers to make unique composite materials. These composite materials are extruded utilizing standard processing machinery.

This product is sourced from Starch, our range is a natural progression in our commitment to make a positive impact on the world around us.

In general, starch-based biodegradable & Compostable resins are more cost competitive than alternative bioplastics. They can accommodate a wide range of physical properties that alternative bioplastics lack, such as tensile strength and heat tolerance。

In general, starch-based bioplastics resins are more cost-competitive than other bioplastics. They can accommodate a wide range of physical properties that alternative bioplastics lack, such as rigidity and heat resistance. Starch composites can also incorporate reused plastics. Our team suggests starch-based plastics when reused plastics should be utilized or if customers require a material that exhibits properties alternative biobased materials can’t display.

Starch-based plastics can be divided into two categories: one is plastics made by blending starch with nondegradable resins (PP/PE/PS, etc.); Another type is plastic made by blending starch with degradable resins (PLA/PBAT, etc.).

Only the latter is biodegradable plastic. We can usually determine whether the product is biodegradable plastic by the "material" on the product label. For example, the nominal materials in the figure are polypropylene (PP) and edible starch, which are not biodegradable plastics.

Photodegradable and thermo oxidative degradable plastics are additive degradable plastics, that is, the so-called "degradation" is achieved by adding degradation additives to traditional PP and PE. The "degradation" process is only the physical fracture of the material, which turns into invisible Microplastics, which is not conducive to the recycling and cleaning of plastics, but also causes greater harm to the environment.

CaCo3 based biodegradable & compostable resin is a kind of PBAT-modified blown plastic with high filling and industrial composting degradation, which has non-degradable organic components.

CaCo3 based biodegradable & compostable resin is one of the most abundant biopolymers. It is completely biodegradable, inexpensive, renewable, and can be easily chemically modified.

Poly (lactic acid) (PLA), as one of the most extensively studied and successfully commercialized biodegradable materials, has excellent gloss and barrier properties but also has drawbacks such as hardness and poor toughness, lack of flexibility and elasticity. Therefore, the blending of high-toughness polybutylene adipate terephthalate (PBAT) with PLA can not only improve the toughness of PLA but also accelerate the decomposition rate of PBAT.

1.1.Modified calcium carbonate enhances PLA toughness and degradation ability

Treated calcium carbonate with aluminate coupling agent (ACA) and successfully prepared aluminate-modified calcium carbonate (Al CaCO3). CaCO3 and Al CaCO3 were melt blended with PLA, respectively, to prepare PLA/CaCO3 and PLA/Al CaCO3 systems and conduct a series of tests.

The mechanical test results indicate that CaCO3 reduces the toughness of PLA, while Al CaCO3 can effectively improve the toughness of PLA. The results of the Proteinase K degradation test showed that the addition of inorganic particles improved the degradation performance of the system and improved the application of materials. Observing the material cross-section, it was found that CaCO3 exists on the surface of PLA, and Al CaCO3 is embedded in the PLA matrix. ACA enables inorganic particles to tightly bind with PLA, thereby improving the toughness of the material.

1.2. CaCO3/PBAT/PLA composite material combines toughness and degradability

We research on the blending modification of PBAT suggests that blending high-toughness PBAT with PLA can not only improve the toughness of PLA, but also accelerate the decomposition rate of PBAT. In addition, D.B. Rocha et al. prepared CaCO3/PBAT/PLA composite materials, and the research results showed that CaCO3 improved the interfacial compatibility between polymers in the matrix, enabling low-cost flexible films to be obtained.

In the future, as the production process matures, its application space is expected to further expand.

Starch based biodegradable & Compostable resin and CaCo3 based biodegradable & Compostable resin both are Biodegradable bioplastics.

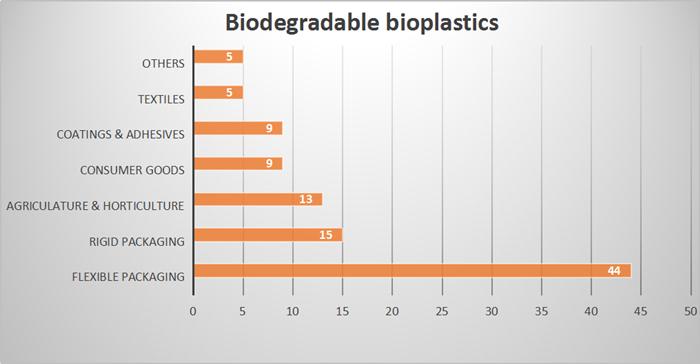

They are very well suited for packaging applications. Indeed, flexible and rigid packaging accounted for about 60 % of their market, followed by agriculture and horticulture.