Polylactic acid (PLA), a plastic substitute made from fermented plant starch (usually corn), is fast becoming a popular alternative to traditional petroleum-based plastics.

Cornstarch pens are made by a number of manufacturers in the EU and China using Mater-Bi or PLA (polylactic acid - a polymer made from lactic acid, fermented from the glucose found in cornstarch) and other revolutionary biodegradable materials made from cornstarch. The biodegradability of the pen body is comparable to cardboard when composted and there are no toxic or metallic residues. Longer-lasting products such as cups and rulers can also be made from corn starch, which takes longer to break down under composting conditions.

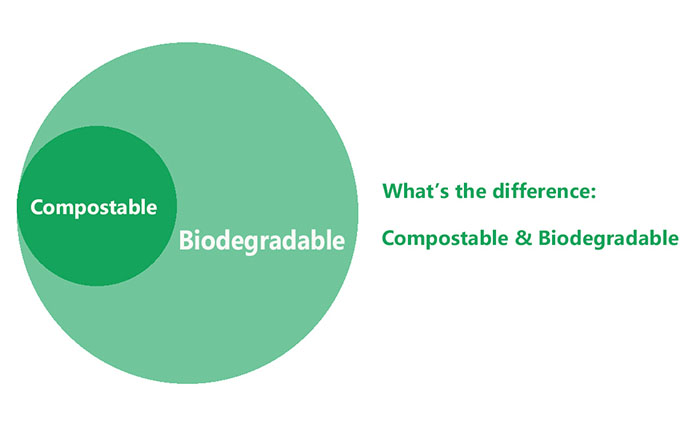

Corn starch products such as pens, rulers, and cups can be made into oil-based plastic substitutes by using renewable agriculturally derived starches to make bioplastic polymers. Cornstarch plastic products look and feel like regular plastics, but they are 100% biodegradable and compostable. Corn starch products are more popular mainly because:

They are made from renewable plant materials

They replace fossil fuel-based products

They are theoretically recyclable if the system is actually in place

They are biodegradable and compostable at the end of their useful life