Cornstarch Biodegradable Resin

Cornstarch biodegradable resin is a type of bioplastic made from cornstarch, a carbohydrate extracted from corn kernels. This resin is an eco-friendly alternative to traditional petroleum-based plastics. It is derived from renewable resources, primarily corn, and offers environmentally friendly characteristics.

The process involves converting cornstarch into a polymer through various chemical treatments. This results in a material that shares similarities with conventional plastic but with the added benefit of being biodegradable and compostable.

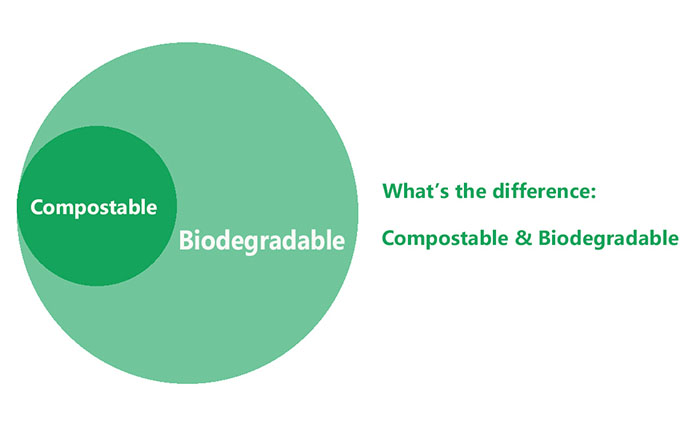

Cornstarch biodegradable resin exhibits properties such as biodegradability and compostability, meaning it can naturally break down into simpler, non-toxic components when exposed to environmental conditions like moisture, heat, and microorganisms. This characteristic distinguishes it from conventional plastics, which persist in the environment for extended periods, causing pollution.

Due to its renewable source and ability to decompose, cornstarch biodegradable resin finds applications in various industries, including packaging, disposable tableware, bags, agricultural films, and more. It aligns with the growing demand for sustainable materials and supports efforts to reduce the environmental impact of plastic waste.

Cornstarch biodegradable resin is a type of bioplastic made from cornstarch, a carbohydrate extracted from corn kernels. This resin is an eco-friendly alternative to traditional petroleum-based plastics. It is derived from renewable resources, primarily corn, and offers environmentally friendly characteristics.

The process involves converting cornstarch into a polymer through various chemical treatments. This results in a material that shares similarities with conventional plastic but with the added benefit of being biodegradable and compostable.

Cornstarch biodegradable resin exhibits properties such as biodegradability and compostability, meaning it can naturally break down into simpler, non-toxic components when exposed to environmental conditions like moisture, heat, and microorganisms. This characteristic distinguishes it from conventional plastics, which persist in the environment for extended periods, causing pollution.

Due to its renewable source and ability to decompose, cornstarch biodegradable resin finds applications in various industries, including packaging, disposable tableware, bags, agricultural films, and more. It aligns with the growing demand for sustainable materials and supports efforts to reduce the environmental impact of plastic waste.