What are starch-based plastics?

Bioplastics can help manufacturing companies remain competitive by meeting growing consumer expectations for sustainability. They are typically derived from a variety of biomass sources, the most widely used being starch, a natural polymer that can be incorporated into a variety of materials. Starch-based plastics can be used in a variety of applications, as they can be combined with various petroleum-based polymers or biopolymers to form unique composites. These composites can then be injection molded or extruded using standard processing machinery.

In general, starch-based plastics are more cost competitive than alternative bioplastics. They can accommodate a wide range of physical properties that alternative bioplastics lack, such as tensile strength and heat resistance. Starch composites can also contain recycled plastics. Our team recommends the use of starch-based plastics when recycled plastics are required or when a customer needs a material with properties that cannot be demonstrated by alternative bio-based materials.

Environmental Benefits

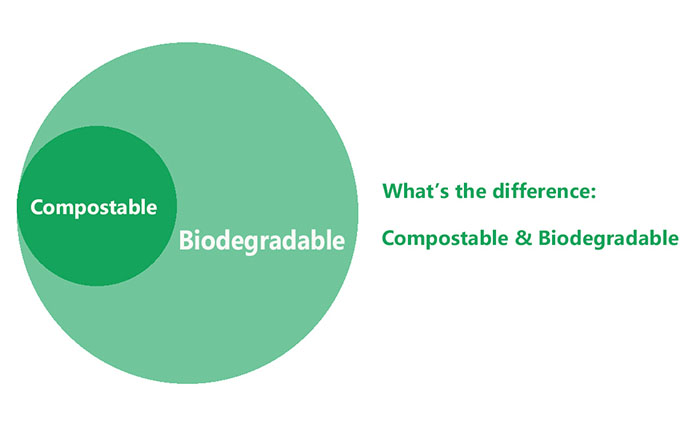

Starch can be used to reduce the carbon footprint of traditional resins because they can replace petroleum-based polymers with natural ones. It is also highly degradable, meaning it can be used with compostable polymers without interfering with the degradation process.